Best Guidance To Care & Maintain Industrial Chillers

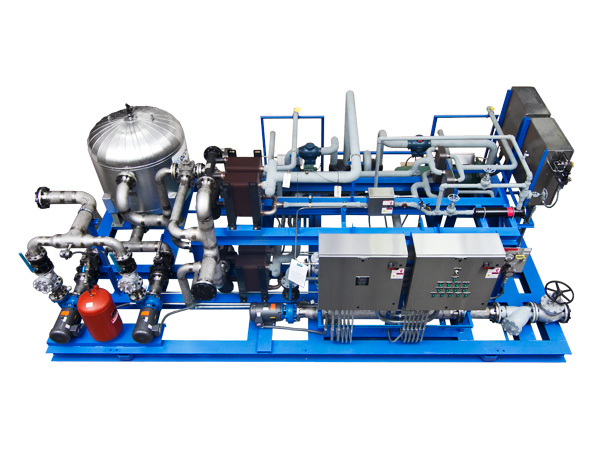

Chillers actually act as a plant’s single largest electrical load supplier. Maintenance works of the chillers involve repairing and cleaning of tubes and ducts, repairing and preventing the leakages of refrigerants, decreasing the operating cost and saving energy. Chiller operation and maintenance in India has reached a new height after the latest developments in centrifugal chillers and magnetic bearing chillers. Latest remote monitoring technologies also help a lot.

Our company Energy Plus India acts as a mechanical project company to provide utility services. So, as an expert here,

We will point out by what techniques you can maintain industrial chillers.

MAINTAIN LOG

If you keep daily or periodical records of temperatures, pressures, levels of fluids and residual precipitation, then this history of operating details will help you understand as to how and when you should maintain your chiller. You can use remote monitoring technologies for continuous monitoring.

KEEP THE TUBES CLEAN

To get high performance, you need to ensure that the heat transfer through the pipes remains efficient. Make sure that there is no dirt, residual minerals, ores, mud, scale, algae present in the pipes. Approach temperatures indicate heat transfer efficiency, and higher approach temperatures indicate that heat transfer is not efficient. You must clean the condenser tubes at least once a year.

TREAT CONDENSER WATER

Condenser water loops use open cooling sources to cool; such water needs to undergo treatment to remove scale, residue, and biological dirt. Otherwise, heat transfer will be affected and the effectiveness of pipes and ducts will decrease. Inspect chilled water loops at least once a year.

ENTERING WATER TEMPERATURE SHOULD BE LOW

If you keep the entering water temperature low, then your chiller’s efficiency will increase.

CHILLED WATER FLOW RATE

Chilled water flow rate affects the efficiency of a chiller. Low flow rate decreases the efficiency. The minimum flow rate should be approximately 3-feet per second (FPS). High flow rate causes vibration, noise, and erosion of tubes. The maximum flow rate should be approximately 12 FPS.

MAINTAIN REFRIGERANT

Amount of coolness of a chiller depends on the amount of refrigerant which passes through the compressor. Prevent the leakage of refrigerant and prevent air and moisture, which will cause increased efficiency.

MAINTENANCE OF HARDWARE

Analyze the lubricating oil of the compressor once a year. If necessary, then change the oil. You need to prevent high moisture to improve purge run hours. Check the oil filters, and if the pressure drops, then you need to change them. You don’t need to take this headache for magnetic bearing frictionless chillers.

Regularly check and remove faults from the entire electrical system which involves starters, gears, motors, wiring etc.

SPEED DRIVES

You can install variable speed drives to save energy. These drives match the motor efficiency and lower the inrush current during starting of motors.