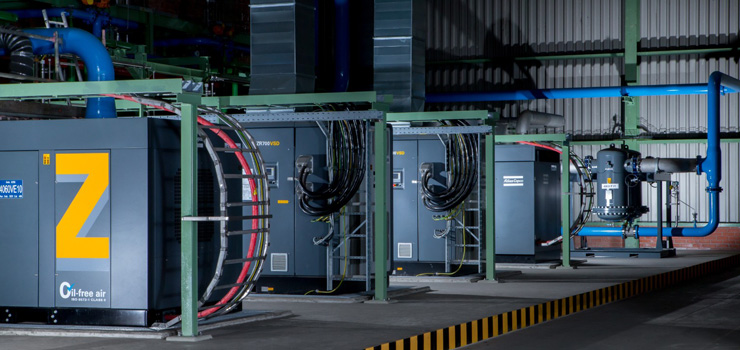

Air compressor enables air pressure control for effective production. Air compressors are diverse in nature with different functionality and applications. Listed below are the different kinds of Industrial Air Compressor.

Types of Industrial Air Compressor

Classification of air compressor can be carried out in different ways but the most popular one is based on the principle of its operation. This way the air compressor is divided into two large categories named – Positive Displacement Air Compressor and Roto-Dynamic Compressor.

Positive displacement compressor classifications

These compressors are further divided into reciprocating and rotary compressor. Reciprocating and rotary compressor can be of various types as stated in the chart.

| Reciprocating Compressor | Rotary compressor |

| In-line compressor | Screw compressor |

| V-shaped compressor | Vane type compressor |

| Tandem-piston compressor | Lobe and scroll compressors |

| Single-acting compressor | |

| Double acting compressor | |

| Diaphragm compressor |

Rotodynamic compressor

Under this category, we have a centrifugal compressor and axial flow compressor.

Now let us understand the most popular types of air compressors…

Reciprocating In Line Compressor –

This is the most widely used air compressor

Simplest in design

Has a varying pressure tag

Directly driven by electric motors or diesel engines

V-shaped compressor –

Air cooled compressor –

Has two cylindrical head unit with concentric valves mounted on each

Single acting compressors –

It has piston at one end

Double acting compressor –

These have two sets of suctions and delivery valves on both sides

Compressed air delivery is continuous in comparison to single acting compressor

Rotary compressor –

These are not reciprocating in nature. They do not have any piston and crankshaft. They are efficient in low air pressure requirements.

The various classification of air compressor enables you to select the best for your farm as per requirements.

At Energy Plus, we understand the value of maintaining air compressor and are always prepared with any kind of air compressor operation in India. With our increasing list of satisfied customers and years of experience, we cannot lay enough stress on how much air compressor maintenance can avert future complexities.

As one of the leading industrial utility service provider, we have plethora of maintenance services to offer to keep your business and industry run with the right pressure but not under it.